Renaissance of a classic

This page is dedicated to the Renaissance program.

In our projects section there are also detailed photos for other projects that we have worked on .

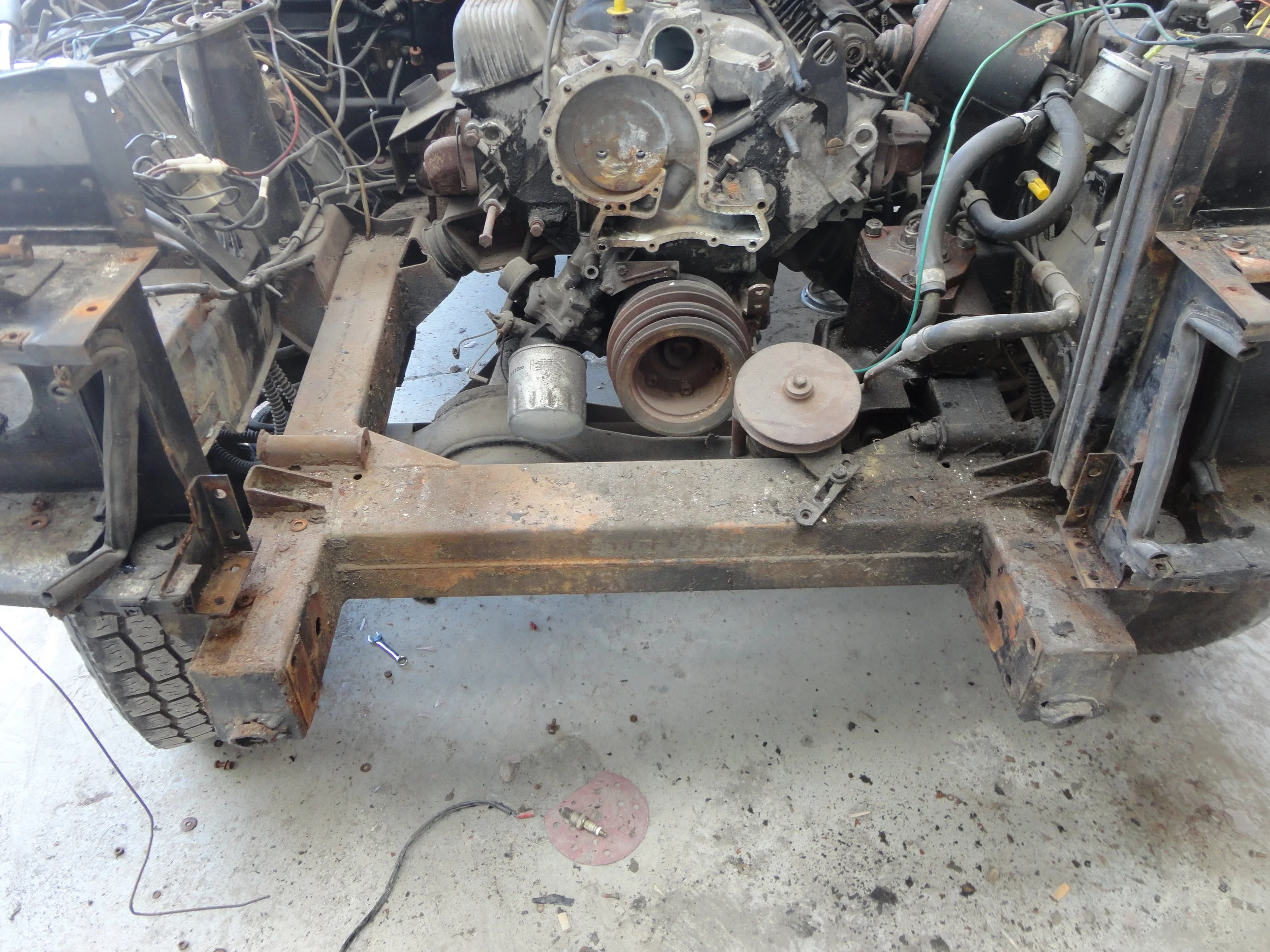

The donor

This red one below is a typical base of vehicle for our work. The chassis has no rust, the body panels are relatively in good condition, and the car came with boxes of the remaining parts.

For the extent of our work which is comprehensive this starting point does not need to be perfect. In this car below the worst part is the damaged dashboard. Previous owner had installed auxiliary gauges on the top section of the dash. It is nearly impossible to source a LHD dashboard in good condition.

Dismantling

Once the car is in our workshop, we totally dismantle it and components are sorted and work begins in several fronts at the same time.

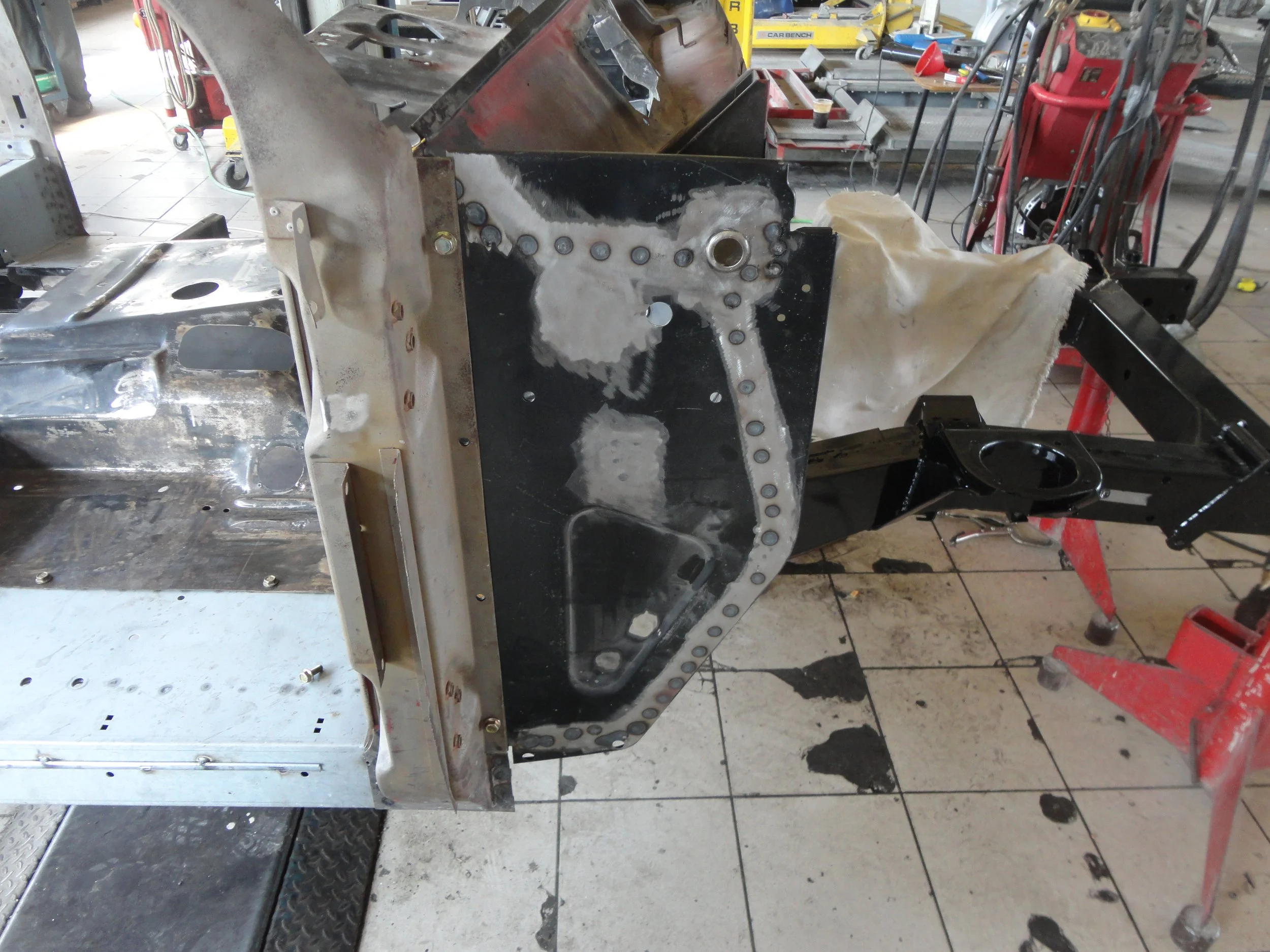

Body Restoration

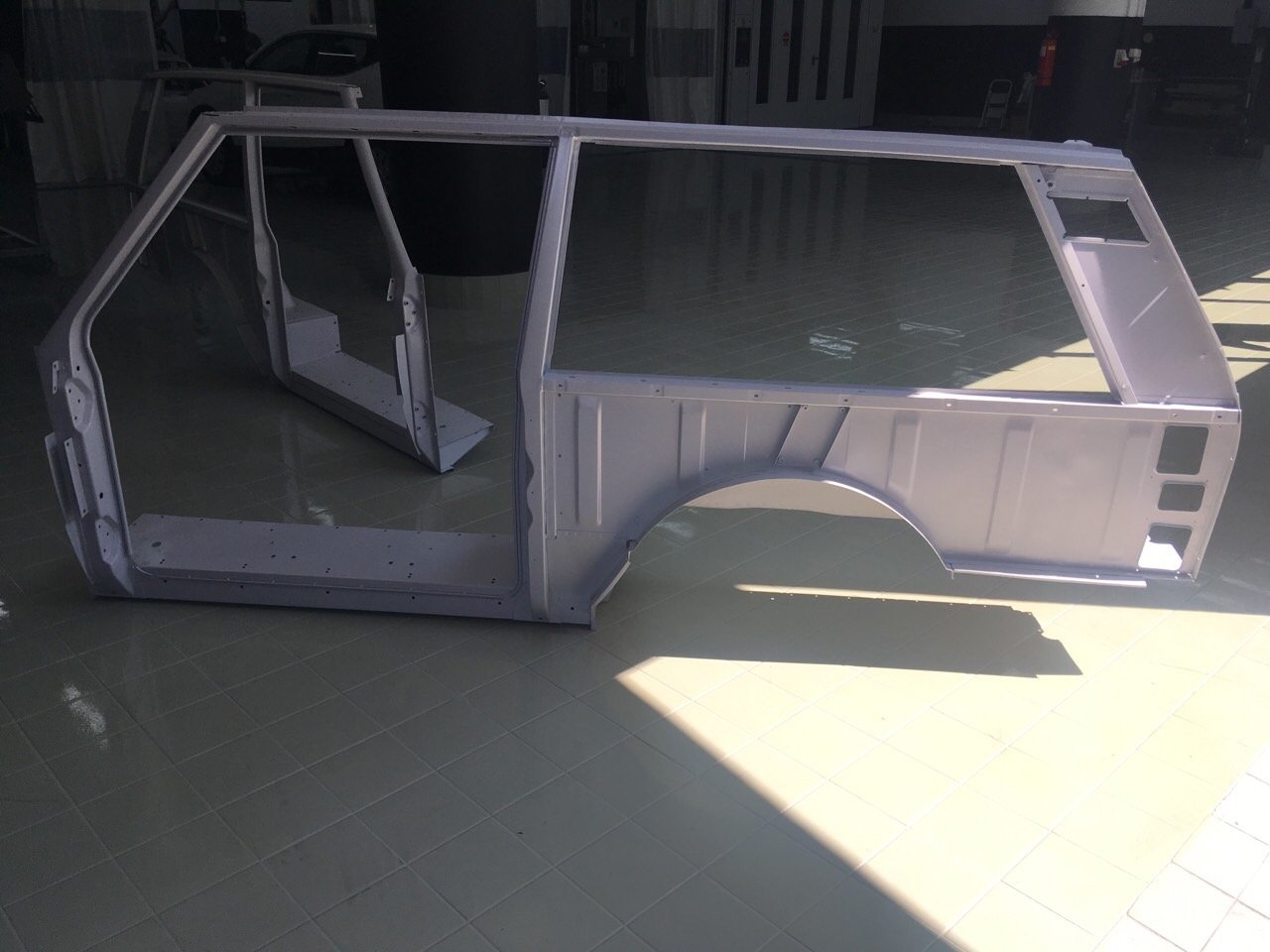

Every component is striped of paint, and restored using replacement components. We use paint striper, or dry ice blast on the majority of the surfaces. In areas where there is rust we use grid blasting. Restoration is done on each component, and then later these are dry fitted before they send to the pain shop.

Most shops, simply remove the external parts, and then repair the body shell as one piece. We prefer to totally separate the components as in many areas there is damage between the mating surfaces, and the seal material is perished, thus not protected from water ingerss.

Painting

Components receive surface preparation and base primer. Modern sealants are applied on the joints.

To ensure ultimate finish we go to extent of separating the under bonnet frame and the user skin, to ensure that even hidden surfaces perfectly coated. Once coated they are reasembled.

Next we apply 3M stone guard protection coating on all the external exposed areas, as well as on all the underfloor exposed section, for durability.

Once ready we apply modern water based paint coats finishing with a clear coat.

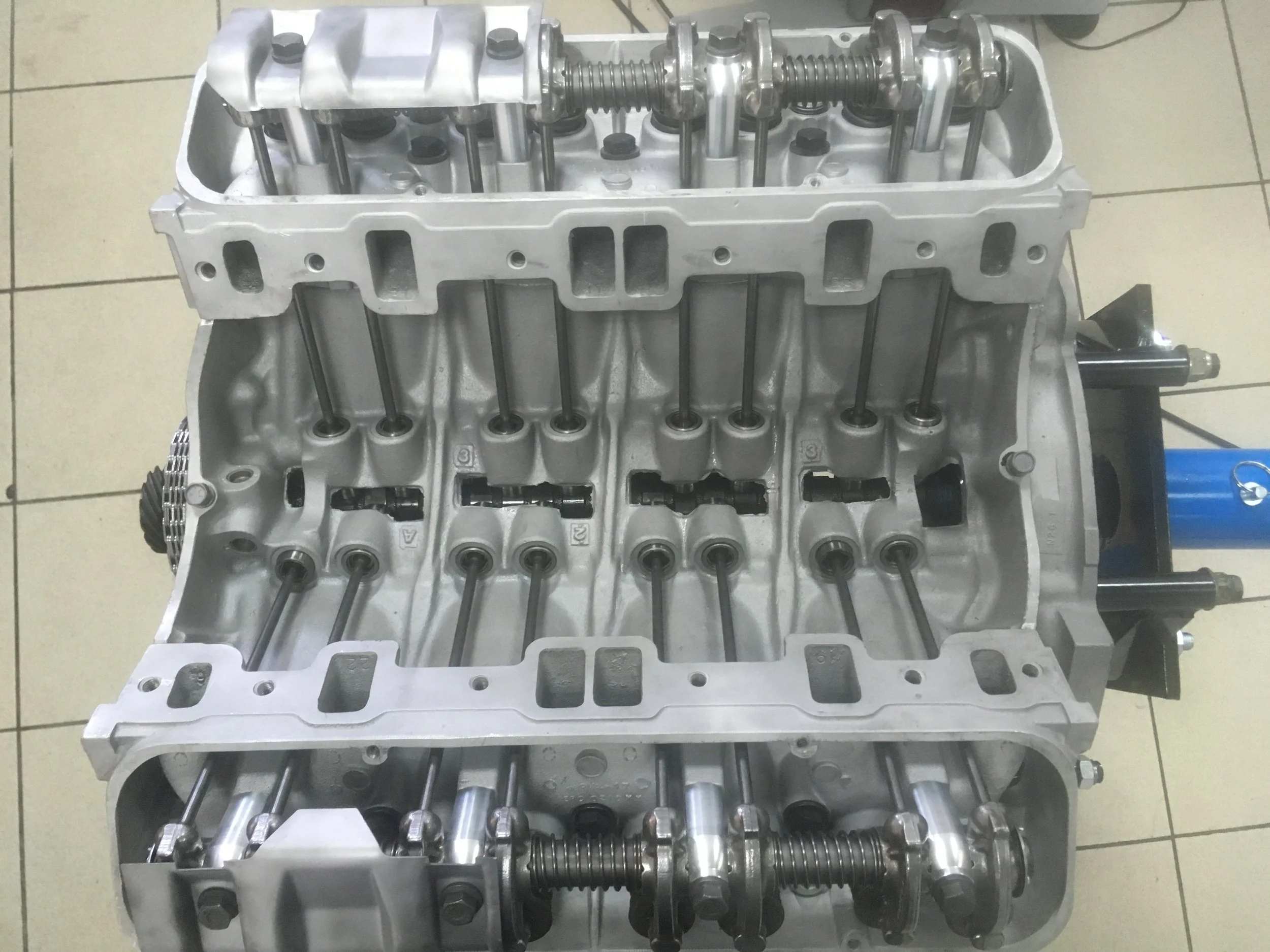

Engine work

We blueprint our engines in the same way we prepare our high performance racing engines.

Once the casings are chemically cleaned the block is measured in all its critical dimensions for straightness, and bore diameters. It is the send to the machine shop and cylinder are usually rebored to the first oversize dimension. Deck surfaces are machined , and crank supports are verified for true alignment.

Once back from the machine shop the block is thoroughly cleaned again and assembled. As standard we renew the following components:

New Pistons, piston rings, and piston pins.

New Bearings, gaskets, bolts

New Valve gear , Camshaft, tappets, pushrods, rocker arm assembly, valves, valve springs, valve guides with modern seals, valve gear and chain. 3angle valve seats,

New Oil pump, oil pressure relive valve, water pump, viscous clutch.

New electricals, Sensors, Alternator, Starter (upgrade to gear driven) , ignition system and distributor. We modernize by using the ultimate 123 type digital distributor, and new spark leads and plugs

New clutch, pressure plate and bearing.

New service items such all Water pipes and vacuum pipes, belts and filters.

New Ancillaries such as fuel pump , fuel filters , water radiator, and power steering pump

New exhaust system from the manifold, in some cases we use a Stainless steel model.

Carburetors are refurbished and calibrated by specialist, using new parts.

Exhaust manifolds coated with heat resistant material

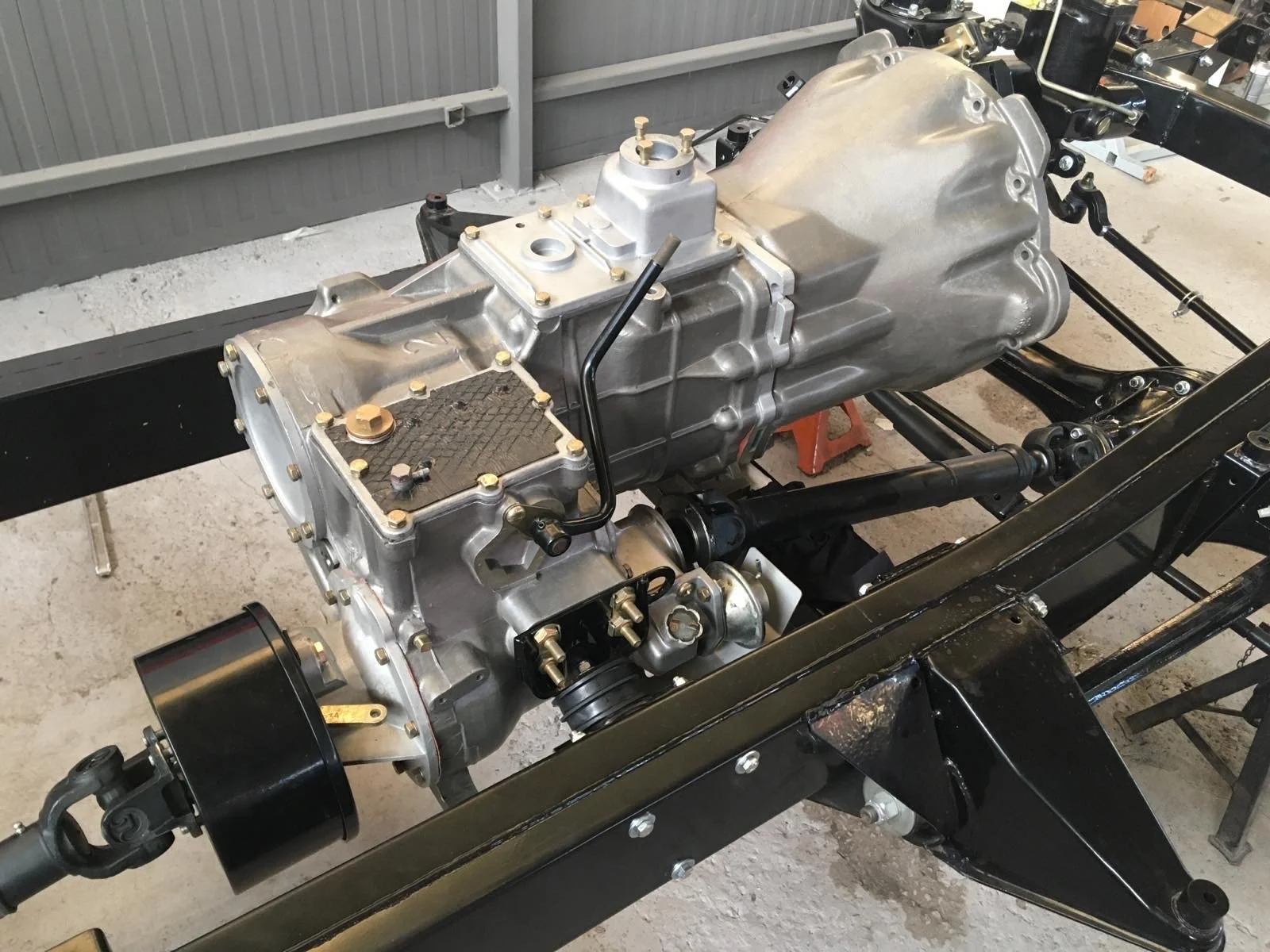

Gearbox and Transfer Box

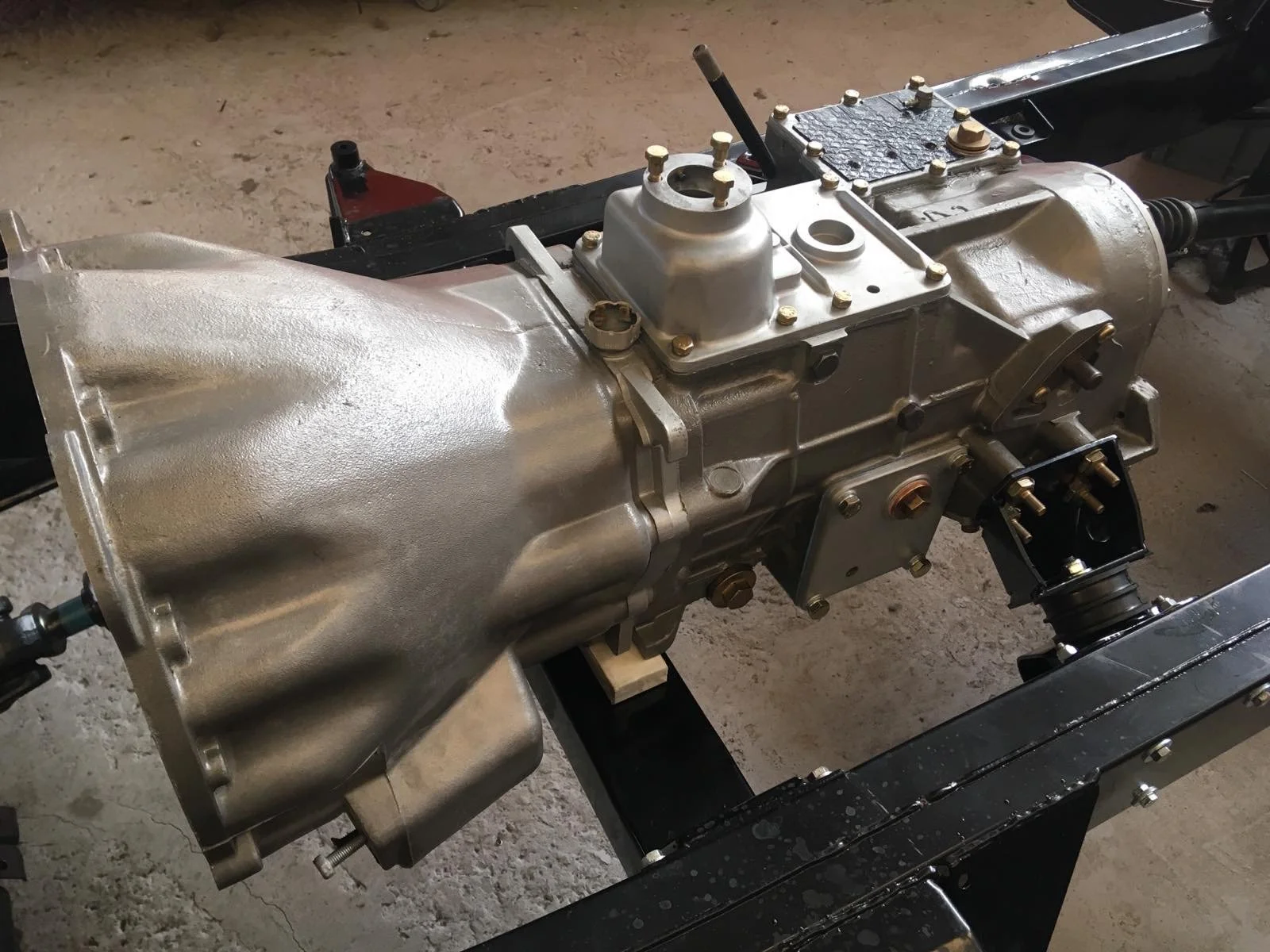

The Land Rover LT95 4speed gearbox is a very strong and reliable gearbox. However its operational finesse compared to modern gearboxes leaves a lot to be desired. The Gear selector is sloppy, the gear wine quite hi, and it is quite clunky when decelerate and reaccelerate. We rebuild our gearboxes in such a way that we eliminate 95% of the negative experience and revived ones give the user a refined operation experience.

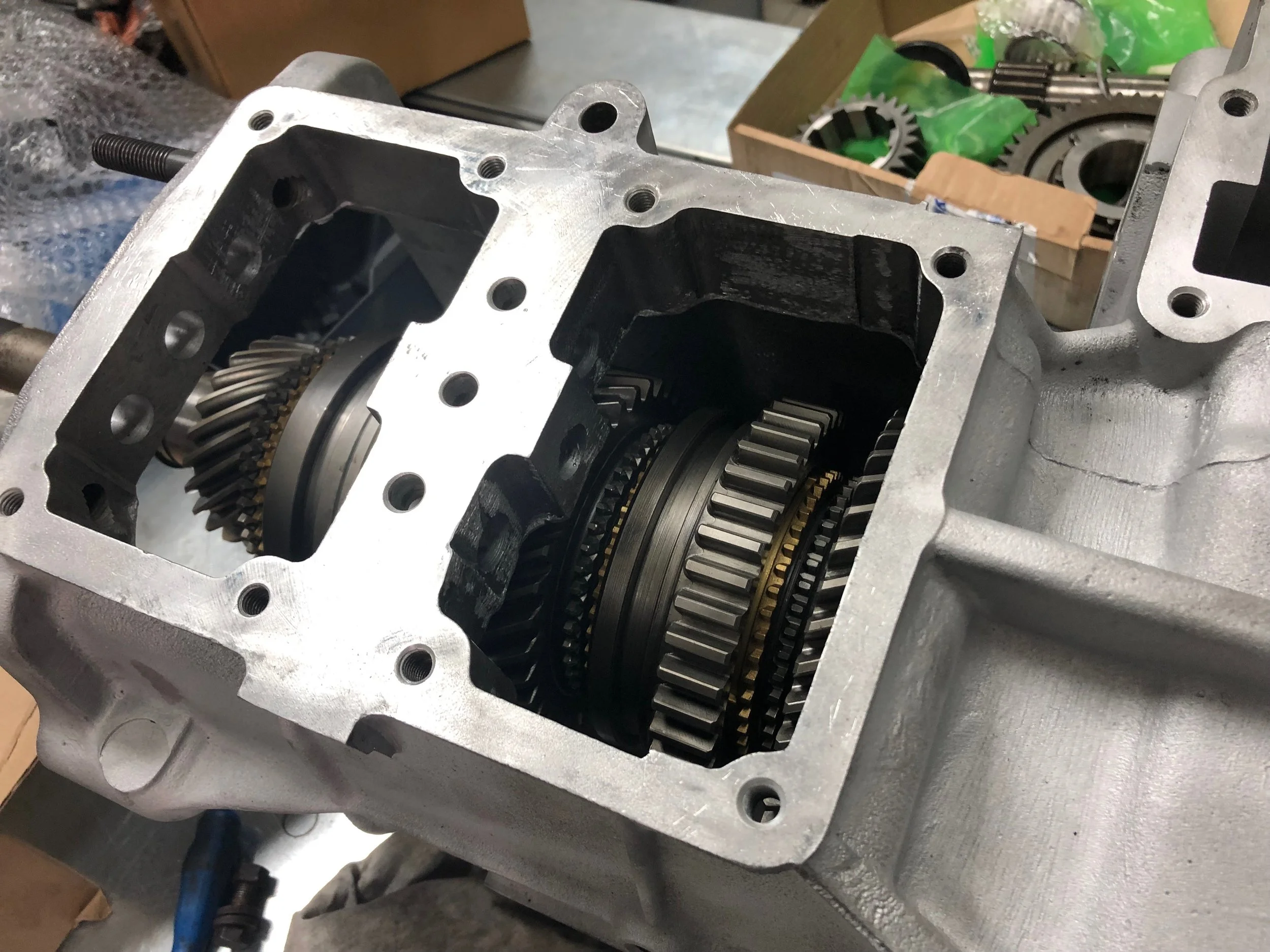

We dismantle the box, and inspect each component. The case is chemically cleaned.

Certain parts need significant work to fit together properly with tight tolerances, which a major cause of slack and sloppiness.

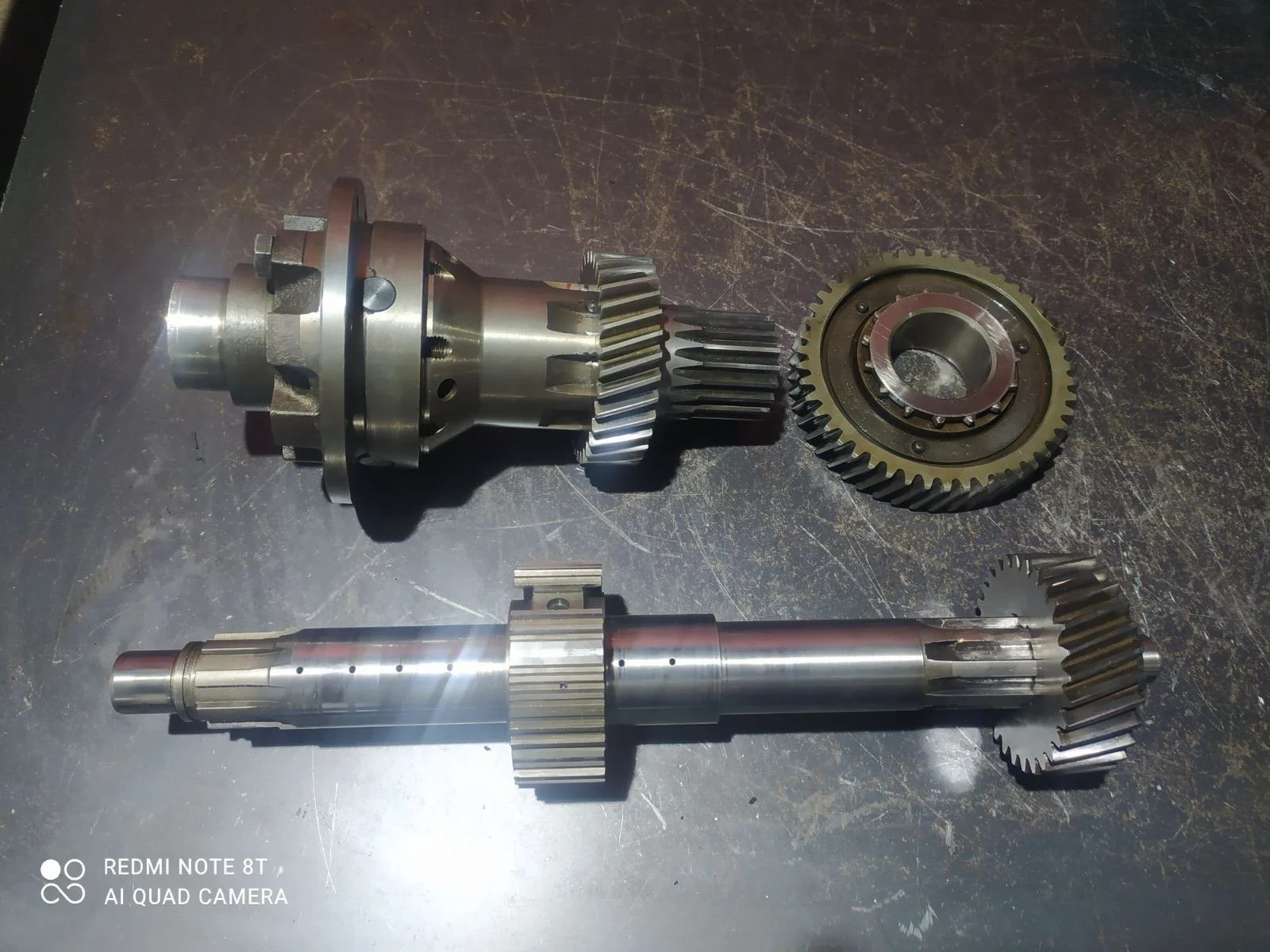

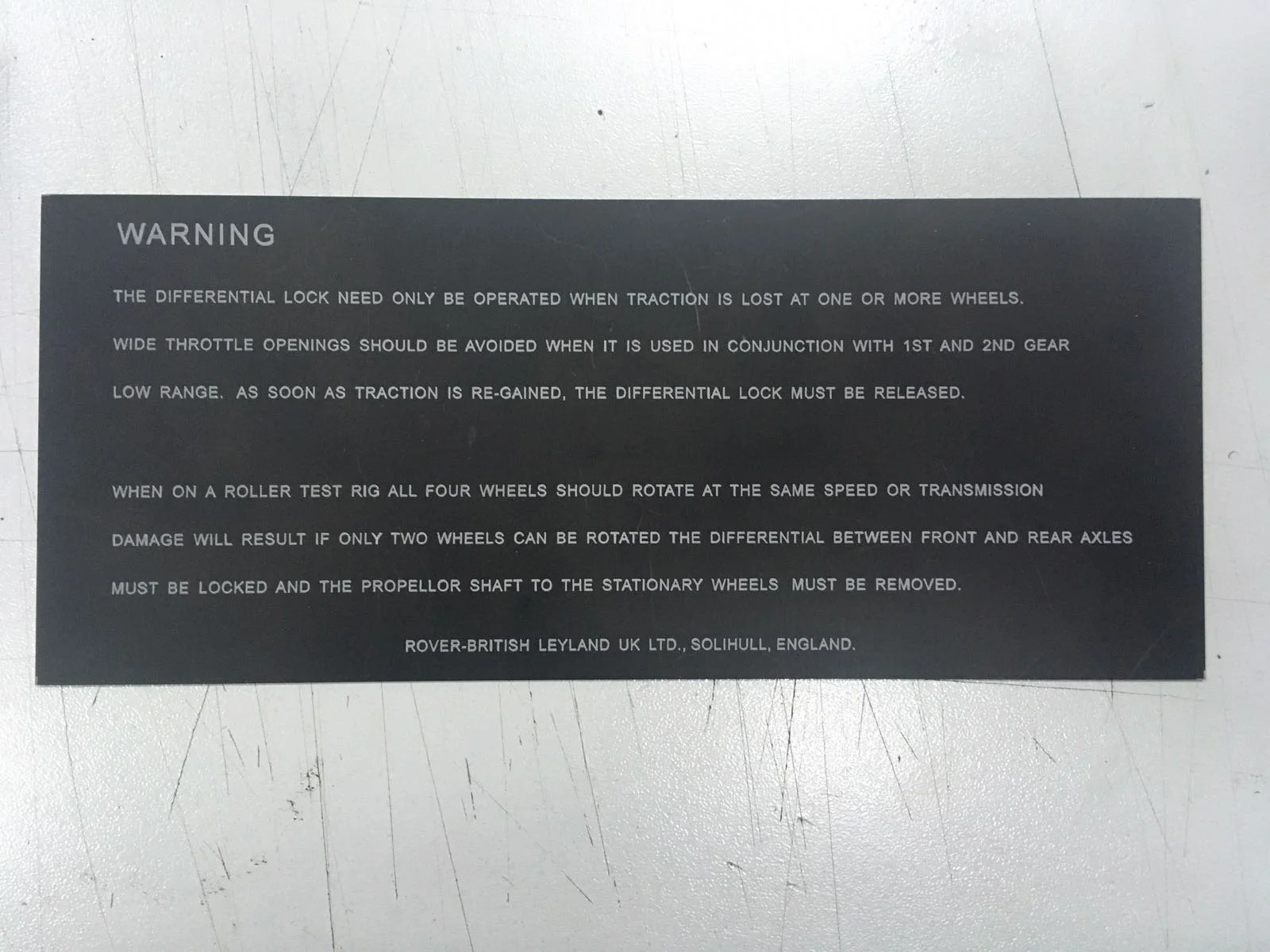

The Center differential is rebuild with new gears, new thrust washers, new pins, we rectify the thrust surfaces , and upgrade them with lubrication groves.

The transfer gears are usually the source of noise, usually because they are warn and because they fit loosely on the output shaft. We replace the gears and fit them tightly on the output shaft.

The gearbox section is assembled using tight tolerances and correct bearing preloads.

We replace with new all synchros, bearings, seals, selector slubs, oil pump & filter, clutch bearing, and slave cylinder.

Finally the handbrake mechanism is renewed with all new components, and a shaved drum.

Differentials, suspenssion, Brakes

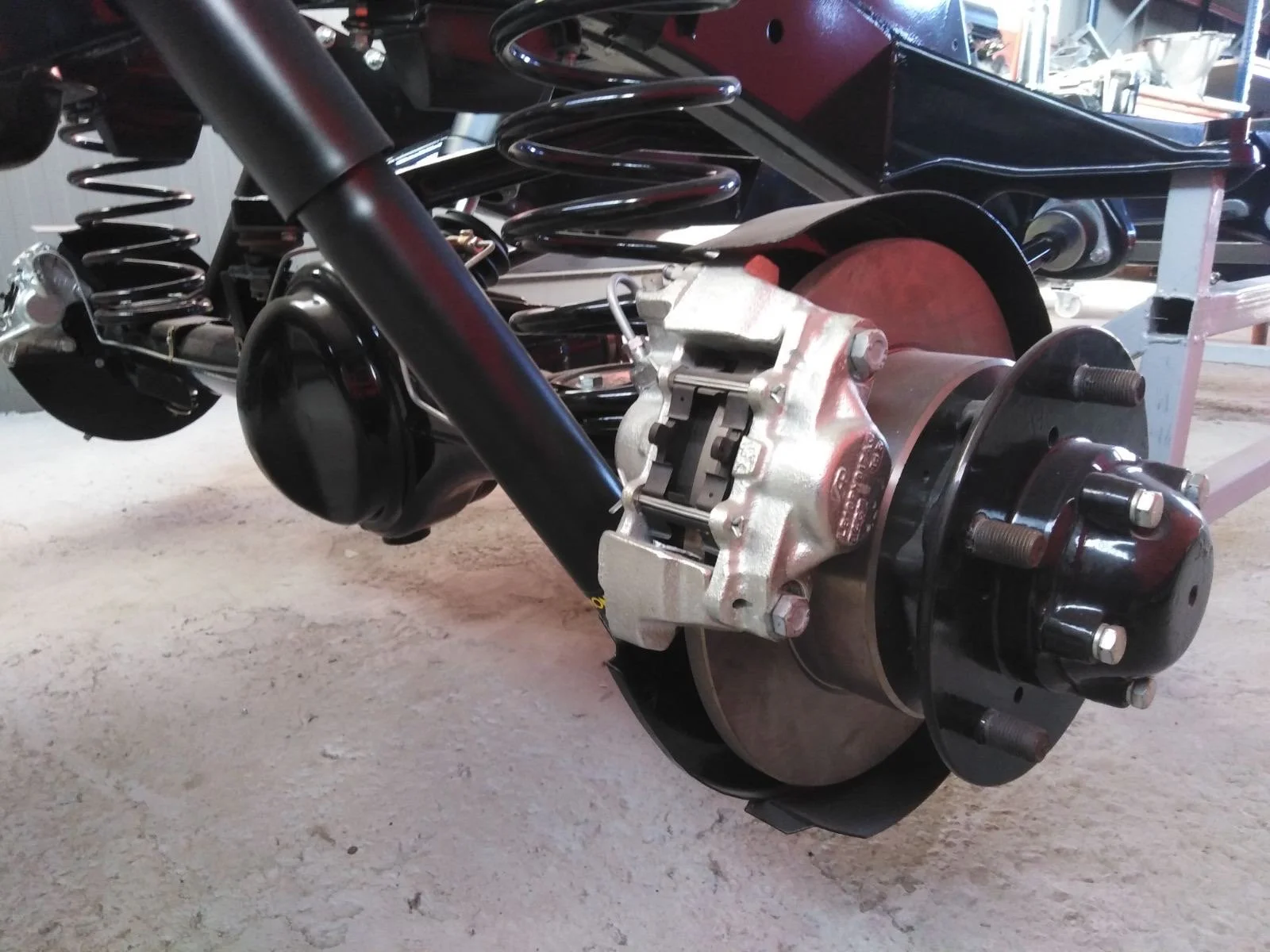

Axles are completely dismantled, inspected and powder coated . Once totally clean they are assembled as follows

Differentials are overhauled with New planetary gears, New ring & pinions as necessary, New bearings, New axle jokes, and New seals.

Axle Uprights. New Swivels, New CV’s, New Bearings, New seals.

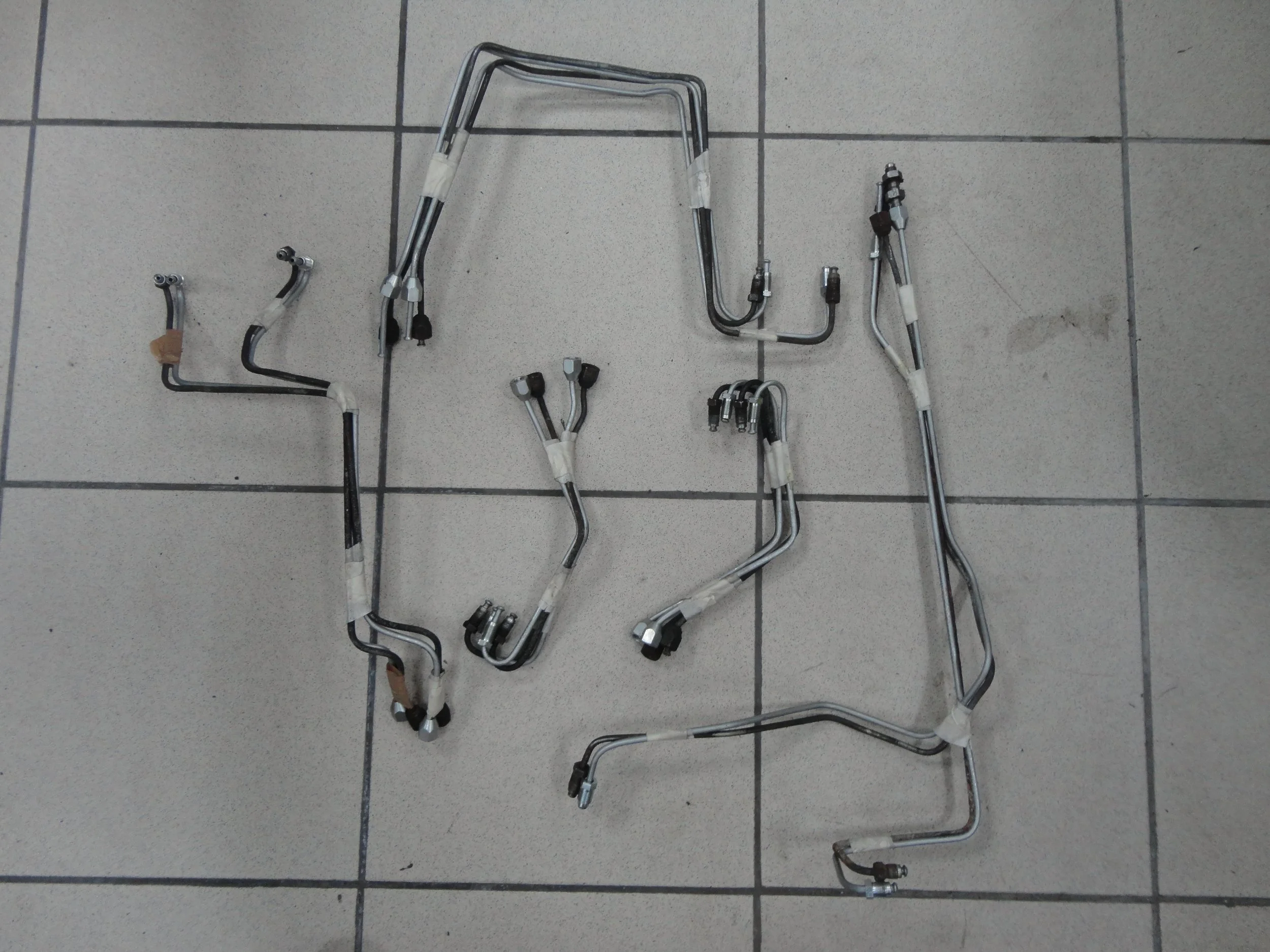

Brakes, New brake lines, New disc rotors, New calipers and pads, remanufactured Servo booster, New master cylinder, New distribution valves

Steering New bars with balljoints, and New steering stabilizer, remanufactured steering gear, New shafts and couplings.

Suspension New shock absorbers, New springs, all New bushes, New bolts and nuts, and a factory remanufactured Hydromat.

Chassis

The selection of the chassis is done when we select the cars we purchase for restoration. It is maybe the most important criteria in our inspections. Once the chassis is free it is grit blasted and inspected for any defects. Once blemishes are rectified it is send to be coated. We us a bonding base coat and then it is powder coated for durable surface.

Interior Upholstery

While Jobs on the body progress , the interior is being prepared. The interior is a far significant job than one may initially estimate. It is important for us as it directly impacts the user experience.

Optically it should be perfect, other details like the tactile feel of the materials, the support of the seats, the feedback of the controls should be better than new.

Once seats are removed from the car, they are totally taken apart. Mechanisms are restored and plated, their frames are powder coated. Then they are re-assembled using New supports and New cushions, New seatbelts, New trims, New headrests, Naturaly the seat are covers with period correct materials , such as Herringbone cloth or Alambra PVC in palomino.

The roof panel upholstery is New, the door panes New, the spare tyre and tool cover also New.

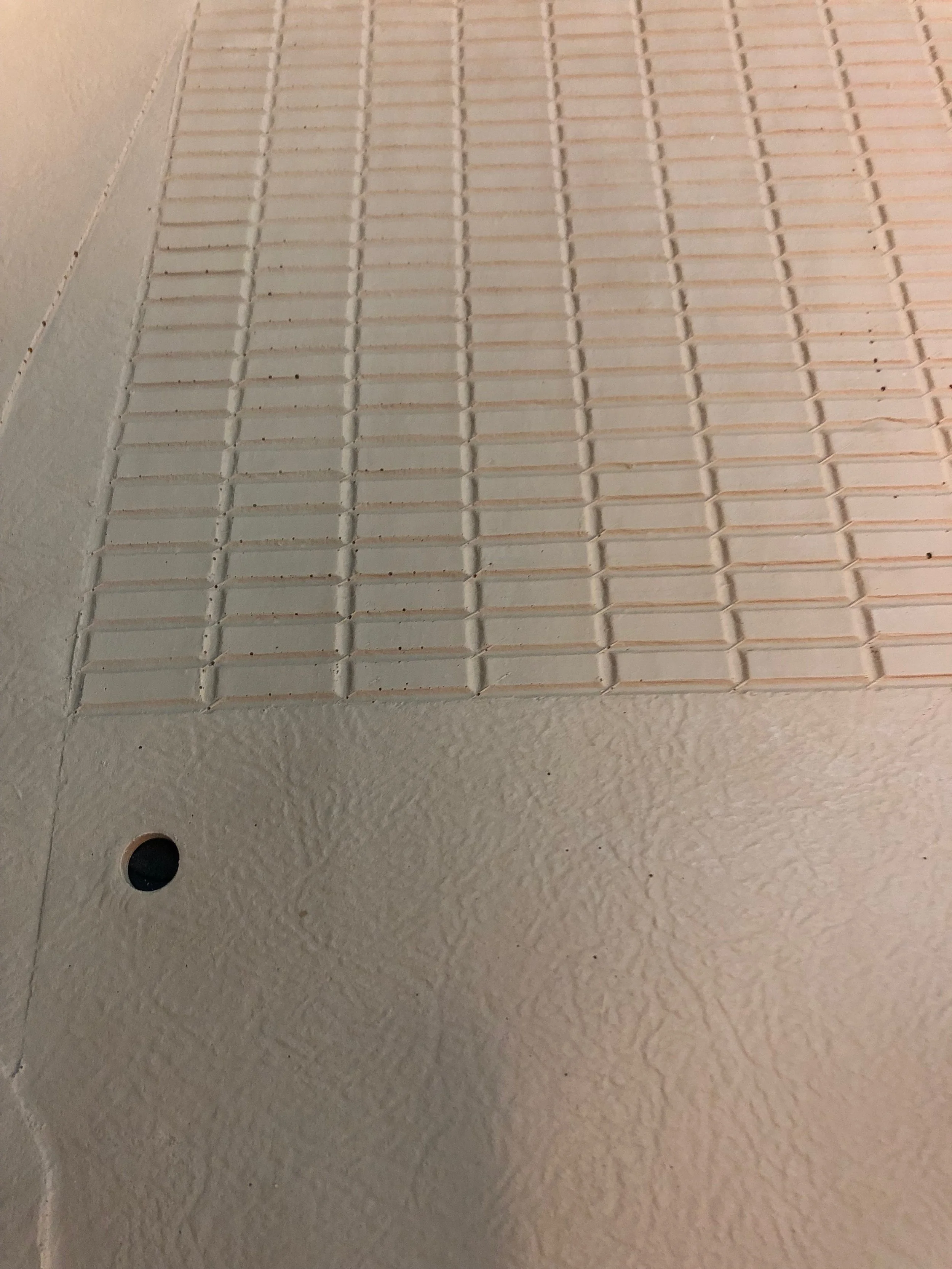

The carpets are New from original material featuring the thick pile. Even underneath the carpets the characteristic rubber mats are New. The one for the rear passengers is unobtainable as new, so we have our own molds and make our own.

Dashboard Instruments

The user experience has to be top. The dash instruments and controls are the items that the driver and passengers are the interface with the machine. The operation has to be flawless. Tactile feedback from the steering , the touch with the leather wheel, the engagement of the switches, and the aesthetic of the instrument cluster, the gauges and the controls, must be that of a new car.

The dash panels are a nightmare to perfect. Usually the donors have been treated to various accessories over the car’s life and most dash panels have various damages from fitted gauges, switches etc. We go to tremendous effort to source and restore items equivalent to the original state.

Instrument clusters are rebuild using New gauges, New casings, all New switches and knobs, New locks, New keys.